FORTÉ PERFORMANCE SYSTEMS

COMMERCIAL & INDUSTRIAL HEAVY DUTY DIVISION

WHAT IS A DIESEL PARTICULATE FILTER (DPF)?

All engines must meet the 2011 low emissions standards (Tier 4) with an integrated Diesel Particulate Filter exhaust after treatment and a cooled exhaust gas recirculations (EGR) system incorporated with the engine. The cooled EGR system enables clean combustion with NOx reduced by 45% compared to Tier 3, while the DPF exhaust after treatment system reduces particulate matter by over 90% from engine exhaust.

HOW DO DPF’S REMOVE PARTICULATE MATTER (PM)?

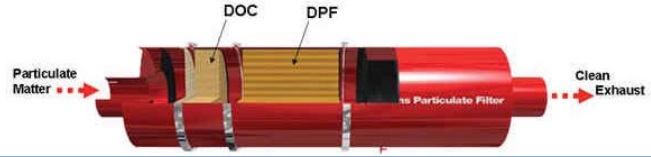

DPF’s in most cases replace the Tier 3 muffler and provide equivalent or better sound reduction. The DPF consists of four sections: an inlet, a Diesel Oxidation Catalyst (DOC), a DPF and an outlet. Exhaust flows out of the engine and into the DPF. It passes through the DOC and then into the DPF where PM is collected on the walls on the DPF.

The PM collected is then oxidized to remove it from the DPF. This is known as regeneration. When operating conditions maintain sufficient exhaust temperatures, the DPF is continually self regenerating. This is known as passive regeneration and results in a clean exhaust exiting the tailpipe. In ideal design situations, an active self-regeneration may be required to remove a build-up of PM in the DPF, due to insufficient exhaust temperatures. This is expected to occur on an infrequent basis.

WHAT IS PASSIVE REGENERATION?

Modern diesel engines are designed to maximize the use of passive self-regeneration. This occurs when operating conditions maintain sufficient exhaust temperature, therefore enabling continuous oxidation of the PM. Passive self-regeneration is completely transparent to the operator and does not effect the machines operation or performance. Diesel engine designers have assumed in the design process, that most new engines operate at a high enough engine load factor for the DPF to self-regenerate in passive mode the majority of the time.

WHAT IS ACTIVE REGENERATION?

Active self-regeneration occurs when there is not sufficient heat in the exhaust to convert the PM being collected in the DPF. Exhaust temperatures are raised by injecting a small amount of fuel upstream of the DPF. the resulting chemical reaction over the DOC raises exhaust gas temperatures high enough to oxidized the PM from the filter. This is all done without any operator intervention. Engine designers have in theory designed the system to minimized the need for active self-regeneration. The overall fuel consumption increases due to active regeneration of the DPF is designed to be barely measurable – approx. 0.1% for most applications. However, in the field under normal operating conditions, it has been proven to be substantially more. In addition, the designers stipulate that the majority of active regenerations will be less than 1% of the total operating time.

WHAT IS A STATIONARY REGENERATION?

Stationary, or parked, regeneration is the same as active regeneration but takes place while the equipment is not being operated. It offers the equipment operator the option, if needed, of performing regeneration outside the normal duty cycle. According to engine designers, this option may only be required in a very limited number of applications. However, once again, this has not been experienced in the majority of vehicles actually in use.

WHAT SERVICE DOES THE DPF REQUIRE?

The DPF is supposed to be service-free up to 5,000 hours when low ash oil is used and the base engine is properly maintained. The normal warranty on the DPF is 2 years from the purchase of the vehicle. At that point, normally ash cleaning is required. The EPA has set minimum ash cleaning intervals of 4,500 hours for engines above 173 hp (129kW). Most engine manufacturers expect the DPF to reach 5,000 hours before ash cleaning is required.

WHAT CREATES ASH IN THE DPF?

Ash is an incombustible material derived from the additive pack in the lube oil. All engines consumer a small amount of oil as part of their normal operation. The oil is burned in the combustion chamber along with the fuel, and the resulting amount of residual ash from the oil is rapped in the filter section of the after treatment system. Ideally the vast proportion of the ash is pushed through the filter and released into the atmosphere. During filter regeneration, the PM is oxidized and removed from the filter. However, all of the ash cannot be oxidized and some remains in the filter.

HOW IS THE DPF SERVICED?

Most Manufacturers require the DPF to be removed and cleaned by a Manufacturer approved cleaning method and an authorized technician. The cleaning process is supposes to take approx. 30 minutes, plus the time to remove and replace the DPF from the equipment. Unfortunately for vehicle owners, most of the dealers involved in servicing these DPF units, the time charged is often up to three days with average costs of more than $1,500.

WHAT IS THE LIFE OF THE DPF?

DPF’s are designed to last the life of the engine. In practice this has not been the case and many owners have experienced catastrophic DPF failure with replacement required.